CNC Steel Processing

Services we provide

Providing solutions for CNC Steel Processing

For support, we will process structural and tubular steel sections and the plates, saving you time and the hassle of conventionally processing steel. Our facilities also have CNC rail-sawing and drilling capabilities, in other words our production is efficient and accurate.

Project management (structural steel)

Design coordination and management

3D modelling

Steel detailing

Precast concrete detailing

Value engineering (structural steel)

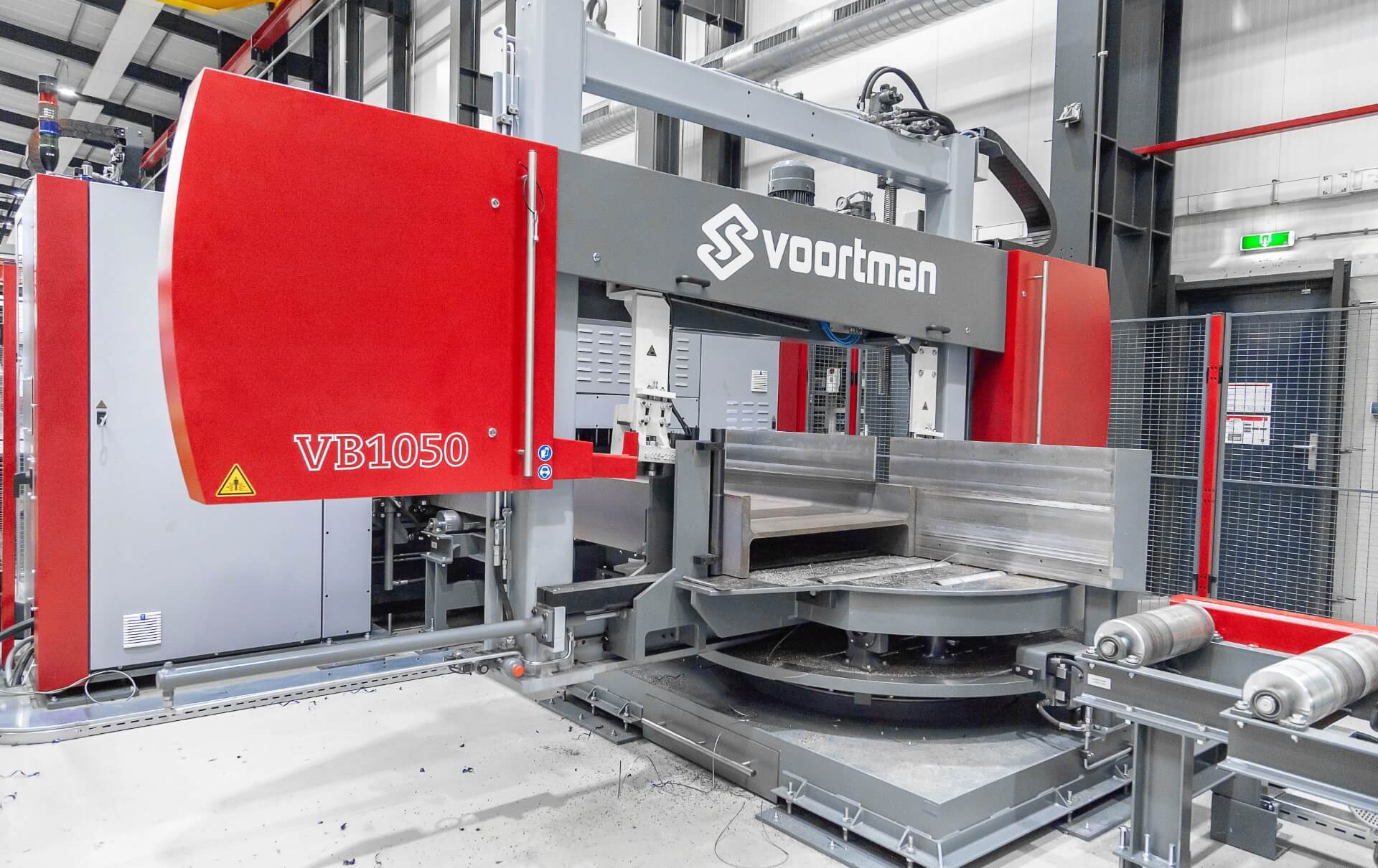

Voortman Steel Group

Lighthouse Engineering partnered with Voortman Steel Group because we have the latest technology in CNC steel processing.

When compared to older plasma or drilling ONLY technologies, the latest in fully automated high-speed milling offers higher cost/time efficiency, better consistent tolerances, more job flexibility and far better machining finishing quality. Enabling scribing in shop drawings will increase fit-up accuracy at the shop. We also have a separate steel saw and drill line that can drill various RAIL sections (Light rail 22 & 30 kg/m, Standard Rail 41-68 kg/m, and crane rails 75 & 86 kg/m).

Project Showcase

Our portfolio of projects includes airports, medical centres, research laboratories, university buildings, manufacturing centres and many hospitality sites including hotels, restaurants and cafes.

Here are a few of our projects:

Inside the factory, our talented people work with the best tools.

Our fabrication shop is filled with skilled tradespeople and the tools they need to transform raw steel into the materials that best serve your construction requirements. Our CNC equipment is comprehensive and networked to our design software systems. And, when the time comes, our fabricators will be there to help you install these metal items at your construction site.

We are a SCA accredited steel fabricator, which means our fabrication and welding processes comply with AS/NZS applicable standards including AS 4100, AS/NZS 5131 and AS/NZS 1554.1.